Industrial 4G/LTE Communication Systems for Rapid Deployment on Remote Sites

- Vinayak Khattar

- Dec 27, 2025

- 4 min read

Industrial communication deployments are no longer confined to controlled indoor environments. Today’s projects span shipyards, highways, tunnels, campuses, parking facilities, and remote industrial zones, where speed of deployment, system reliability, and total cost of ownership are critical.

Traditional wired communication systems, whether analog PBX or VoIP, struggle in these conditions due to trenching requirements, distance limitations, and ongoing maintenance overhead.

Industrial 4G/LTE communication systems provide a faster, more resilient alternative, enabling rapid deployment of rugged, IP67/IK10-rated communication endpoints with minimal infrastructure, optional solar power, and built-in support for audible and visual alerts.

Real Problem with Traditional Industrial Communication

Deploying communication systems across shipyards, highways, mining operations, tunnels, campuses, or remote industrial sites exposes a hard reality that Project Managers and IT/OT teams encounter repeatedly. Traditional wired communication models break down at scale.

Whether based on PBX and analog systems or SIP and VoIP endpoints, these architectures are constrained by an unavoidable Iron Triangle of deployment that balances cost, speed, and reliability.

Where Traditional Systems Fail

Budget Overrun: A wired deployment is rarely about the devices themselves. The real cost comes from trenching, conduit installation, cable runs, switches, cross-connects, and skilled labor, which often exceed the endpoint hardware cost by multiples.

Time Delays: Cable planning, excavation, fiber or copper installation, termination, testing, and network certification routinely stretch deployments into weeks or months, making rapid commissioning impossible.

Rigid Placement Limits: Ethernet-based systems introduce strict distance constraints, most notably the 90-meter limitation, which severely restricts where safety phones, hotlines, and operational endpoints can be installed across large or distributed sites. Power availability and environmental exposure further limit viable locations.

The result is consistent across projects, with capital expenditure increasing sharply, deployment timelines extending significantly, and long-term maintenance risk becoming unavoidable. In modern industrial environments that demand speed, flexibility, and operational resilience, these approaches are no longer efficient or defensible.

4G Cellular Technology: The Practical Alternative to Wired Communication

Industrial 4G/LTE communication systems remove fixed infrastructure from the equation entirely.

Instead of extending networks to devices, the device becomes the network edge using public or private cellular connectivity to deliver instant, site-wide communication without trenching or switching infrastructure.

Rugged 4G industrial phones and intercoms are purpose-built for harsh environments and operate as fully standalone endpoints.

Why Industrial 4G/LTE Communication is Better Than Wired Systems

Industrial 4G/LTE communication removes the structural limitations of wired systems by eliminating fixed infrastructure and centralized dependencies. This results in faster deployment, greater resilience, and lower overall project cost in demanding industrial environments.

1. Infrastructure Elimination

No copper or fiber runs

No switches, PBX hardware, or MDFs

No distance limitations

Result: Massive reduction in deployment time and capital expenditure.

2. Rapid Time-to-Operation

Typical installation completed in hours, not weeks

Mount, power, insert SIM, configure

No network engineering dependencies

3. Environmental & Vandal Resistance

IP67 weatherproof protection

IK10 impact resistance

Suitable for outdoor, exposed, and high-risk locations

4. Decentralized Reliability

No single point of failure

Immune to cable cuts or central PBX outages

Each endpoint operates independently

5. Remote and Off-Grid Deployment Capability

Supports AC, DC, battery, and solar power

Eliminates power trenching requirements

Enables deployment in isolated or infrastructure-poor locations

6. Audible and Visual Call Signaling

External loudspeakers for loud ringing or paging

High-intensity strobe lights (Flasher) for optical call duplication

Ensures call awareness in high-noise or low-visibility environments

These capabilities are delivered through LightCom rugged 4G industrial phones, purpose-built for plug-and-play deployment and proven in demanding industrial environments.

Simple Deployment Process

Mounting Install the IP67-rated phone(e.g., our LC101-AD-H-FB-4G Outdoor Hotline Phone) at the required location. and connect optional Loudspeaker and Strobe Light accessories.

Power & Connectivity Connect to AC/DC power or solar battery system. Insert a standard SIM card.

Hotline Programming Program speed dials or automatic hotline calls for instant response.

That’s it. The system is live.

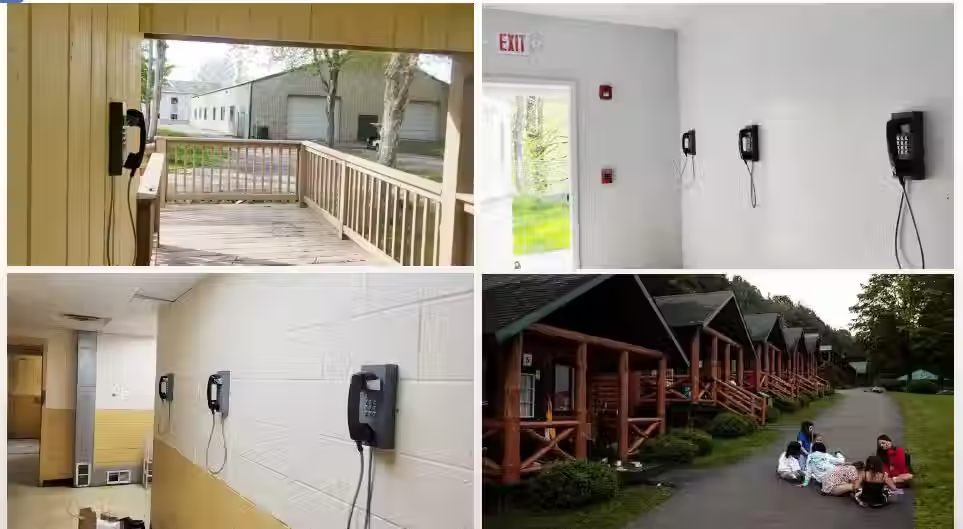

Proven Use Cases Across Industrial Environments

Industrial 4G/LTE communication is already deployed successfully across a wide range of demanding environments, where traditional wired infrastructure is impractical, costly, or slow to implement, including the following use cases:

Ship repair and shipbuilding yards

Highways, tunnels, and toll roads (emergency call boxes)

Large university and industrial campuses

Parking facilities and transport hubs

Remote recreational areas and camps

Anywhere trenching is expensive, slow, or impractical, 4G cellular technology becomes the most logical architecture.

💡 Ready to Simplify Your Next Deployment?

LightCom has successfully deployed hundreds of rapid-response communication systems on sites ranging from summer camps and ship repair facilities to toll roads and parking complexes.

Stop wasting budget on copper cable and trenching.

➡️ Contact our industrial communication experts today. Get a free consultation on how 4G Solar-Powered Telephony can revolutionize your next deployment and cut your TCO immediately.

Operational Impact of Industrial 4G/LTE Communication

Industrial 4G/LTE communication systems fundamentally change the economics of site-wide industrial communications by reducing total cost of ownership, accelerating commissioning timelines, improving system resilience, and minimizing ongoing maintenance requirements.

Projects that continue to rely on copper cabling, conduit, and centralized PBX extensions incur unnecessary cost, extended deployment cycles, and avoidable operational risk.

Comments